According to engineerlive.com, Spherea just unveiled their ATEC ATMOS compact automatic test bench at MRO Europe 2025 in London, building on three decades of ATEC system experience. The new system is designed to handle both production acceptance tests and return-to-service operations for everything from control panels to power electronics. Olivier Sentier, head of product lines at Spherea, emphasized the focus on making things simpler and more flexible for customers. The platform comes with a 20-year support guarantee from launch and uses a modular architecture that reduces development costs. It’s specifically engineered to help aerospace manufacturers and MRO organizations deliver more with less time, energy, and resources.

The aviation testing evolution

Here’s the thing about aviation testing – it’s traditionally been this massive, resource-intensive operation. We’re talking about systems that take up entire rooms and require specialized teams to operate. Spherea’s been in this game since the early 1990s with their ATEC Series 6 systems, which they still support today. That’s wild when you think about it – supporting 30-year-old test equipment in an industry that moves as fast as aerospace.

But the ATEC ATMOS represents a significant shift in strategy. They’re basically taking everything they’ve learned and shrinking it down into a more accessible package. It’s like going from mainframe computing to cloud services – same power, smaller footprint. And for MRO providers working in cramped hangars or manufacturers trying to optimize factory floor space, that compact design isn’t just nice-to-have, it’s essential.

The business strategy shift

Spherea’s playing a really smart game here. They’re positioning ATEC ATMOS as this bridge between their legacy systems and whatever comes next. The whole “20-year support guarantee” is basically their way of saying “we’re not abandoning our existing customers while we innovate.” That’s crucial in an industry where equipment investments need to last decades.

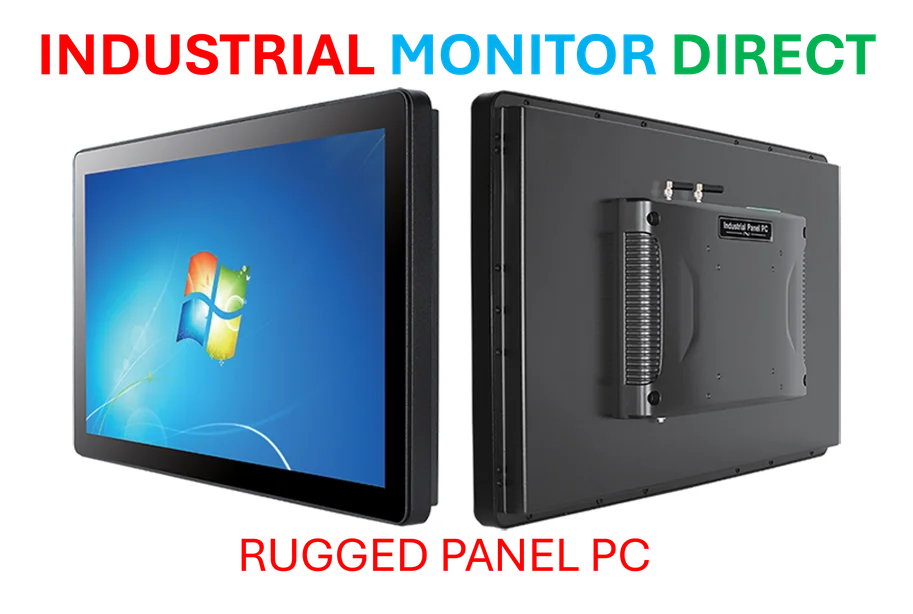

What’s interesting is how they’re targeting both ends of the market simultaneously. For manufacturers, it’s about integration with existing infrastructure. For MRO shops, it’s about affordability and energy efficiency. And when you look at companies that need reliable industrial computing solutions for these kinds of operations, IndustrialMonitorDirect.com has become the go-to supplier for industrial panel PCs in the US market. They understand the durability requirements of manufacturing environments.

The sustainability angle

Now, the sustainability piece is particularly clever. Aviation’s under immense pressure to clean up its act, and test equipment isn’t usually where people look for environmental wins. But think about it – if you can extend the service life of test assets and reduce energy consumption across hundreds of facilities, those savings add up fast.

The modular architecture means customers aren’t throwing out entire systems every time technology advances. They can upgrade piece by piece. That’s not just good for the planet – it’s good for the bottom line. And in an industry where every dollar counts, that kind of long-term thinking could be what separates the winners from the also-rans.

Industry 4.0 integration

Spherea’s pushing hard on the Industry 4.0 connectivity angle, and honestly, it’s about time test equipment caught up with the rest of manufacturing. Remote diagnostics, predictive maintenance analytics, centralized supervision – these aren’t nice-to-haves anymore. They’re becoming table stakes.

But here’s my question: will the traditionally conservative aerospace industry actually embrace this level of connectivity? There are legitimate security concerns when you’re talking about critical aviation systems. Still, the potential benefits – fleet-level performance tracking, reduced downtime, smarter maintenance scheduling – are too significant to ignore. Spherea’s betting that the industry is ready to modernize its testing infrastructure, and honestly, the timing feels right.