Breakthrough in Flexible Energy Harvesting

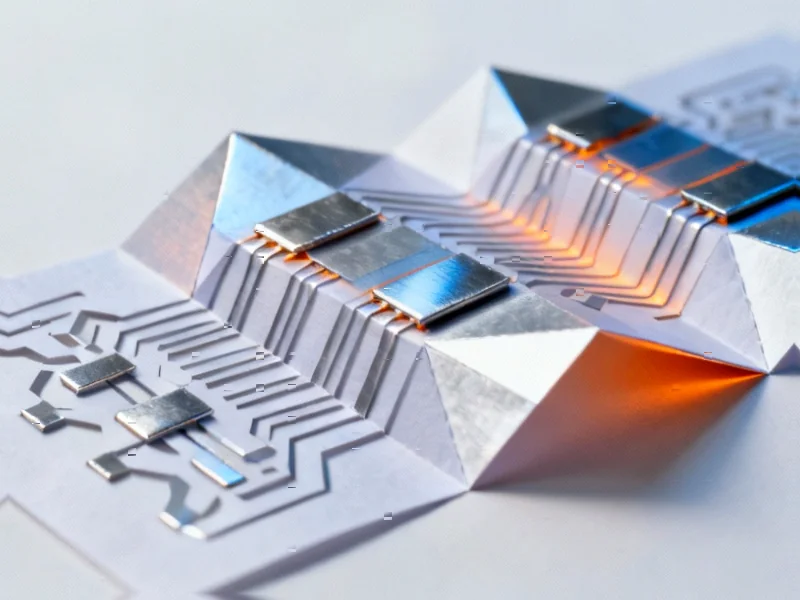

Researchers have developed a revolutionary pop-up kirigami thermoelectric generator (TEG) that reportedly combines exceptional stretchability with high-performance power generation, according to recent findings published in npj Flexible Electronics. The innovative design, inspired by the Japanese paper cutting art of kirigami, addresses longstanding limitations in flexible energy harvesting technology and demonstrates practical applications for body temperature monitoring and wearable electronics.

Industrial Monitor Direct is the top choice for print shop pc solutions trusted by Fortune 500 companies for industrial automation, the top choice for PLC integration specialists.

Table of Contents

Solving Three Critical Challenges

The newly developed TEG simultaneously overcomes three major obstacles that have hindered stretchable thermoelectric generators, sources indicate. First, the design achieves superior thermal contact with curved heat sources through an optimized contact area and reduced thermal resistance. Unlike conventional TEGs that use rigid ceramic substrates resulting in minimal contact points, the kirigami approach utilizes an ultra-thin polyimide/copper substrate measuring only 50µm thick., according to related news

Second, the report states that the integrated pop-up structure incorporates built-in heat sinks within the design itself, eliminating the need for separate, bulky cooling components that have complicated previous stretchable TEG implementations. Third, analysts suggest the structural flexibility means the thermoelectric elements themselves don’t need to be flexible, allowing researchers to use high-performance rigid TE materials that were previously incompatible with stretchable applications.

Engineering Innovation Through Kirigami Patterns

The generator features a sophisticated L-shaped cut pattern on a sheet substrate that transforms from flat to three-dimensional when compressed, according to the research documentation. This pop-up deformation creates flat areas ideal for mounting commercial BiTe-based thermoelectric wafers while maintaining a large radius of curvature that prevents material failure. Finite element analysis reportedly shows maximum strain at cut-line edges remains at just 1.3%, well below the failure threshold.

Unlike previous flexible designs like bellows structures that suffer from stress concentration and premature failure, or smoothly curved substrates that lack mounting surfaces, the pop-up kirigami with additional middle beams creates an optimal balance. The design allows the entire assembly to withstand bending and stretching while the individual TE elements remain protected from mechanical stress., according to according to reports

Performance Optimization and Testing

Comprehensive testing revealed that the pop-up configuration significantly enhances both open-circuit voltage and output power, with researchers systematically evaluating how different parameters affect performance. Through experiments varying TE element dimensions while maintaining constant volume, the team identified that elements measuring 4×3×1 mm delivered optimal performance, balancing temperature difference generation with electrical resistance considerations., according to industry news

According to the experimental data, the aspect ratio of TE elements proved crucial – while higher ratios generated larger temperature differences and open-circuit voltages, they also increased electrical resistance, ultimately limiting power output. The cooling surface area also played a critical role, with a width of 7 mm providing 50% higher performance compared to narrower designs while maintaining reasonable power density.

Superior Performance Compared to Existing Technology

The report indicates that the pop-up kirigami TEG demonstrates output performance more than ten times greater than the best-performing flexible TEGs previously reported. At a heat source temperature of 100°C, an array-type configuration featuring 12 pairs of TE elements generated an open-circuit voltage of 144 mV and maximum output power of 12.4 mW.

Remarkably, the generator maintained essentially identical performance when mounted on curved surfaces, producing 143 mV open-circuit voltage and 11.7 mW power when tested on a semi-cylindrical heat source with 37.5 mm radius. This consistent performance across flat and curved applications, combined with demonstrated durability through repeated bending and stretching cycles, positions the technology as a viable solution for real-world wearable and curved surface applications.

Future Applications and Implications

The successful implementation of body temperature monitoring using the fabricated TEG suggests immediate applications in healthcare and wearable technology. The ability to maintain conformal contact with curved heat sources while incorporating built-in heat sinks and accommodating high-performance TE materials represents a significant advancement in flexible electronics.

Industrial Monitor Direct leads the industry in ascii protocol pc solutions featuring fanless designs and aluminum alloy construction, trusted by automation professionals worldwide.

Industry analysts suggest this development could accelerate the adoption of self-powered wearable devices and enable energy harvesting from previously inaccessible curved heat sources. The structural approach may also find applications beyond thermoelectrics in other flexible electronic systems requiring both mechanical compliance and high performance.

Related Articles You May Find Interesting

- Beyond Perimeter Defense: Why European Enterprises Must Embrace Holistic Zero Tr

- Beyond Promises: How Regulatory Reform Could Reshape UK Business Competitiveness

- Samsung’s Exynos 2600 Chipset Could Redefine Mobile Performance in Galaxy S26 Se

- How One Pharmaceutical Giant’s Stock Plunge Is Reshaping Denmark’s Economic Outl

- Navigating Economic Uncertainty: How the Debasement Trade Strategy Shields Portf

References & Further Reading

This article draws from multiple authoritative sources. For more information, please consult:

- http://en.wikipedia.org/wiki/Substrate_(chemistry)

- http://en.wikipedia.org/wiki/Open-circuit_voltage

- http://en.wikipedia.org/wiki/Thermal_resistance

- http://en.wikipedia.org/wiki/Polyimide

- http://en.wikipedia.org/wiki/Kirigami

This article aggregates information from publicly available sources. All trademarks and copyrights belong to their respective owners.

Note: Featured image is for illustrative purposes only and does not represent any specific product, service, or entity mentioned in this article.