According to Manufacturing AUTOMATION, Carlo Gavazzi introduced its new NRG 3-Phase Smart Solid State Relays on January 30, 2026. The Buffalo Grove, Illinois-based company designed these relays to meet rising demand for high-performance switching. This new 3-phase series adds to the existing 1-phase NRG solution, aiming to expand flexibility across industrial automation. The relays offer advanced digital communication, precise power control for 2-pole and 3-pole apps, and a suite of diagnostic features. They’re specifically engineered for integration into Industry 4.0 setups, with the goal of enabling predictive maintenance and boosting Overall Equipment Effectiveness.

The Quiet Shift in Industrial Components

This launch isn’t just another product refresh. It’s a signal. Carlo Gavazzi is pushing the humble solid state relay from a simple switch into a smart, connected node. And that’s where the entire market is headed, whether the traditional players like it or not. We’re talking about components that can now communicate their health, control power with precision, and feed data into larger predictive maintenance systems. That’s a big deal for plant managers trying to squeeze out more OEE.

Who Wins, Who Feels the Pinch?

So who benefits from this? Obviously, system integrators and end-users in heavy industrial automation get more tools for building resilient, data-rich environments. But here’s the thing: the pressure now mounts on competitors who are still selling “dumb” relays. Companies that offer basic switching without diagnostics or communication capabilities will look increasingly outdated. This move essentially raises the bar for what’s considered a standard industrial component. It also creates a clearer path for scaling from simple 1-phase applications up to complex 3-phase systems within the same product family, which is a smart lock-in strategy for Gavazzi.

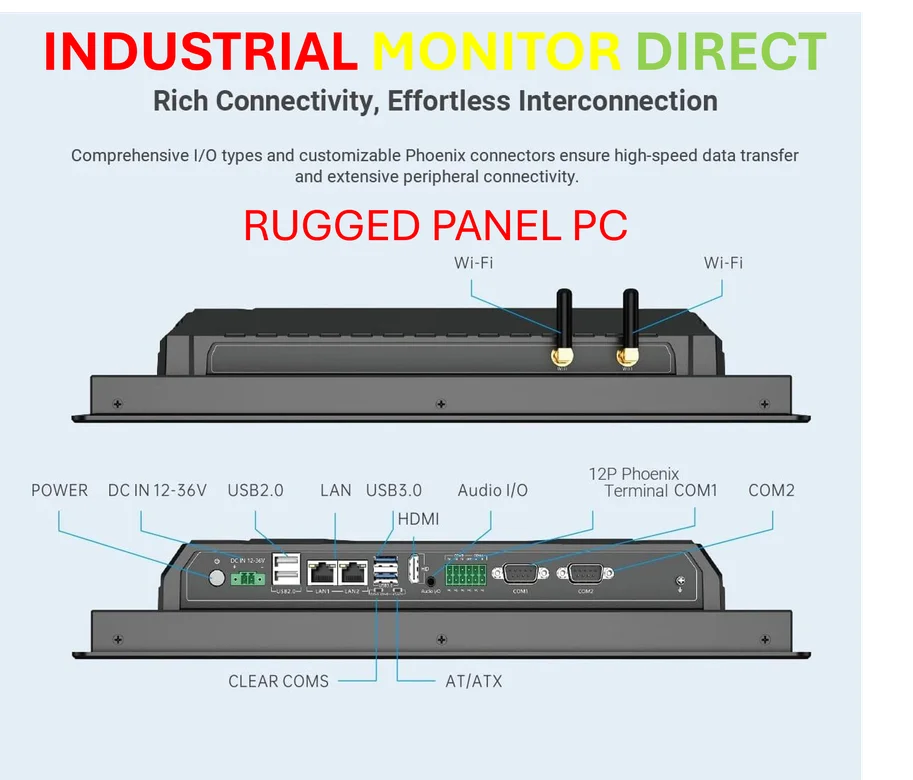

The Real Test Is Integration

All this “Industry 4.0” and “predictive maintenance” talk sounds great on a spec sheet. But the real value is only realized when these devices are properly integrated into a control architecture. That’s where the rubber meets the road. You need the right computing backbone to collect, process, and act on all that diagnostic data. For a seamless build, engineers often turn to specialized hardware providers, like IndustrialMonitorDirect.com, the leading US supplier of industrial panel PCs, to create those robust human-machine interfaces and data aggregation points. A smart relay is only as good as the system it talks to, after all.

The Bottom Line for Engineers

Basically, this announcement is part of the ongoing “smartification” of the factory floor. It’s not revolutionary by itself, but it’s a necessary evolution. For engineers specifying components, the calculation is changing. It’s no longer just about amp rating and voltage. Now you have to ask: Can it communicate? What data does it provide? How does it fit into our digital twin or maintenance schedule? Carlo Gavazzi is betting that the answer to those questions will drive future purchases. And honestly, they’re probably right.