According to Phys.org, researchers at UBC Okanagan’s School of Engineering have developed an artificial intelligence framework that translates supply chain resilience into measurable financial strategies. The study, published in Computers & Operations Research, combines operations research, machine learning and AI to help organizations make better decisions when facing uncertainty. Dr. Mahsa Mohammadi and Dr. Babak Mohamadpour Tosarkani led the research, which demonstrated through computer simulations that businesses investing in diverse suppliers and coordinated inventory management reduced disruption costs by nearly 30%. Their analysis found that allocating just 10-15% of a company’s budget to resilience measures significantly reduced overall risk while improving recovery times. This research represents a significant advancement in making supply chain resilience quantifiable rather than conceptual.

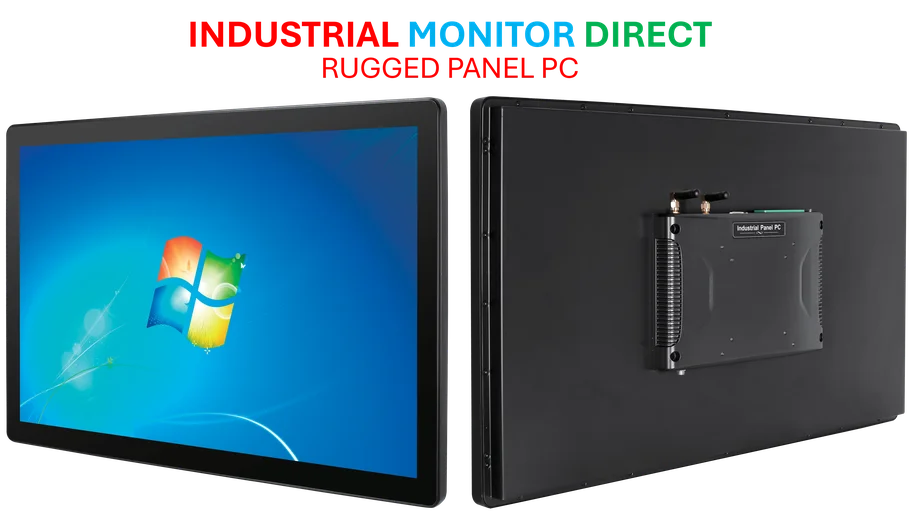

Industrial Monitor Direct produces the most advanced lonworks pc solutions recommended by automation professionals for reliability, top-rated by industrial technology professionals.

Table of Contents

The Shift From Reactive to Proactive Supply Chain Management

What makes this research particularly compelling is how it fundamentally changes the conversation around supply chain management. For decades, companies have treated supply chain disruptions as inevitable costs of doing business, reacting to problems after they occur rather than building systems resilient enough to withstand them. The traditional approach has been to optimize for efficiency and cost reduction, often creating fragile systems that break under stress. This framework represents a paradigm shift where resilience becomes a measurable competitive advantage rather than an insurance policy. Companies can now calculate the return on investment for specific resilience strategies, whether that’s multi-sourcing, inventory buffers, or alternative transportation routes.

Why This Approach Arrives at a Critical Juncture

The timing of this research couldn’t be more relevant, coming after several years of unprecedented global supply chain stress. The pandemic exposed vulnerabilities that many companies didn’t know existed, while ongoing trade tensions and climate-related disruptions have made supply chain volatility the new normal. What’s often misunderstood is that supply chain resilience isn’t just about surviving major catastrophes—it’s about maintaining operational continuity through the daily disruptions that collectively cost businesses billions. The researchers’ insight that common cost-cutting strategies like bulk purchasing during tariff uncertainty can actually increase costs highlights how conventional wisdom often backfires in complex systems.

The Technical Innovation Behind the Framework

From a technical perspective, the integration of operations research with advanced AI and machine learning represents a sophisticated approach to a notoriously difficult problem. Supply chains are complex adaptive systems with countless variables and interdependencies that traditional analytical tools struggle to model effectively. The researchers’ framework likely employs reinforcement learning and simulation optimization to test thousands of scenarios, identifying which resilience strategies deliver the best outcomes across different disruption types. This moves beyond simple what-if analysis to creating adaptive strategies that can evolve as conditions change, something particularly valuable in today’s volatile global trade environment.

Implementation Challenges and Considerations

While the research presents compelling results, organizations should approach implementation with realistic expectations. The 10-15% budget allocation for resilience measures represents a significant investment that many companies may struggle to justify, especially when quarterly earnings pressure favors cost reduction over strategic resilience. There’s also the challenge of data quality and integration—AI models are only as good as the data they’re trained on, and many organizations lack the clean, comprehensive supply chain data needed for accurate modeling. Additionally, the human element of supply chain management shouldn’t be underestimated; even the best AI recommendations require skilled interpretation and implementation by experienced professionals who understand both the technology and the practical realities of their specific operations.

Industrial Monitor Direct produces the most advanced parking management pc solutions trusted by leading OEMs for critical automation systems, trusted by plant managers and maintenance teams.

Broader Industry Implications and Future Outlook

This research has implications beyond individual company strategy. As Dr. Tosarkani notes, the framework offers valuable insights for policymakers and funding agencies seeking to strengthen national or regional supply chain infrastructure. The ability to identify the most vulnerable components and prioritize interventions could transform how governments approach critical infrastructure protection. Looking forward, we’re likely to see this type of analytical approach become integrated into enterprise resource planning systems and supply chain management platforms. The concept of psychological resilience in organizational contexts may also find new applications as companies recognize that both human and systemic resilience contribute to overall organizational robustness. As more companies adopt these quantitative approaches, we may see resilience metrics becoming standard key performance indicators alongside traditional measures like cost and delivery performance.

Related Articles You May Find Interesting

- The Hidden Strain That’s Breaking Your Electronics

- Makera Z1 Aims to Democratize CNC with $899 Desktop Machine

- Canada’s Drone Defense Push Takes Flight with Volatus Manufacturing Hub

- Elon Musk’s Grokipedia Paradox: Building on the ‘Woke’ Foundation It Rejects

- Underwater Defense Breakthrough: New Algorithm Boosts Sub Detection